Heat Shrink Insulating Tubing

Kugwiritsa ntchito

1. Amagwiritsidwa ntchito pamagetsi apakatikati mpaka 36kV

2.Kuteteza ku chinyezi ndi kupanikizika

3.Zoyenera kuthetseratu chingwe ndi chitetezo chapakati cholumikizira

Mbali

1.Hot kusungunuka zomatira kumapereka madzi abwino

2.Coating mtundu: filimu zokutira

3.Kukana kwabwino kwa dzimbiri

4.UV kukana komanso kukana kwanyengo

5.Halogen-free

6.Superior magetsi ndi makina katundu

7.Kuchepa kwa chiŵerengero cha 3:1

8.Wapakatikati khoma

Mbali

1.Chida chogwiritsira ntchito magetsi

2.Kusungunula kodalirika

3.Superior hermetic kusindikiza

4.Kutentha kwakukulu / umboni wozizira, wosalowa madzi, Anti-kukalamba,

5. Amagwiritsidwa ntchito kwambiri pamagetsi amagetsi, zamagetsi, mafuta, engineering yamankhwala, zomangamanga ndi kulumikizana

Kupanga kutentha shrinkable chubing ayenera choyamba kusankha masterbatch yoyenera, ndiyeno kusankha zipangizo wothandiza kupanga enieni.

Chophimba cha nyumba yotentha.

1. Kupanga kwa chubu chowotcha kutentha ndikoyamba kupanga polyene leech masterbatch: kuphatikiza zida zosiyanasiyana za polyene leech m'munsi ndi zida zosiyanasiyana zothandizira.

Zidazo zimayesedwa molingana ndi chiŵerengero cha chilinganizo ndiyeno zimasakanizidwa: zinthu zosakanikirana zimayikidwa mu mapasa-screw extruder ndi pelletized kuti apange polyene leech functional masterbatch.

2. Njira yopangira mankhwala: malinga ndi mawonekedwe a mankhwala, njira ziwiri za extrusion imodzi wononga ndi jekeseni akamaumba angagwiritsidwe ntchito.

Kwa processing ndi kupanga:

1. Single-screw extrusion type: yomwe imagwiritsidwa ntchito kwambiri popangira mapaipi owukira kutentha, monga machubu a khoma limodzi lotha kutentha, machubu otha kutentha awiri okhala ndi guluu, komanso makulidwe apakatikati.

Mapaipi owukira pakhoma, mapaipi otenthetsera kutentha kwa mabasi, mapaipi otenthetsera kutentha kwambiri ndi zinthu zina zonse zimakonzedwa ndikupangidwa ndi phula limodzi.

Mzere wopangira machubu otenthetsera kutentha uyenera kukhala ndi zida zotsatirazi: extruder (kupanga chubu lakuya), nkhungu yopanga, thanki yamadzi ozizira, chipangizo chomangika, ndi

Disk chipangizo, etc.

2. Kumangira jekeseni: kumagwiritsidwa ntchito kwambiri popanga zida zowoneka bwino zowotcha, monga zisoti zowukira kutentha, masiketi aambulera omwe amatha kutentha, machira a chala osatentha ndi zinthu zina.

Onse amagwiritsa ntchito jekeseni, ndipo zida zopangira ziyenera kuphatikizapo makina opangira jakisoni ndi jekeseni.

3. Chotsatira chofunikira ndi kulumikizana ndi ma radiation.Zopangidwa ndi extrusion kapena jekeseni akamaumba akadali liniya mamolekyu nyumba.

Kapangidwe, mankhwalawa alibebe "ntchito yokumbukira", ndipo ntchito ya kukana kutentha, kukana kukalamba, ndi kuvala kukana sikukwanira.

Sinthani kapangidwe ka maselo a chinthucho.Njira yomwe timagwiritsa ntchito nthawi zambiri ndikusintha kwa ma radiation: ma electron accelerator radiation crosslinking, cobalt source radiation.

Kuphatikizika, peroxide mankhwala kuwoloka, panthawiyi molekyulu amasintha kuchokera liniya maselo dongosolo dongosolo maukonde.Zogulitsa zowonjezera zikudutsa

Pambuyo pa kugwirizanitsa, zimakhala ndi "memory effect", zomwe zimathandizira kwambiri kutentha kwa kutentha, makina, ndi mankhwala a chubu chowotcha kutentha.Tebulo lenileni

Tsopano chubu loyikira kutentha lasintha kuchoka ku mkhalidwe wololera kupita ku zosagwirizana, kukana kukalamba, kukana abrasion, ndi kukana dzimbiri kwa mankhwala.

4. Kukulitsa: Chopangidwa chosinthidwa ndi ma radiation crosslinking kale chili ndi "mawonekedwe a kukumbukira", ndipo chimakhala chokwera kwambiri.

Kuchita kosasungunuka pansi pa kutentha.Pambuyo Kutenthetsa pa kutentha kwambiri, vakuyumu kuwomba ndi kuzirala, amakhala yomalizidwa kutentha shrinkable chubu, ndiyeno malinga chubu.

Mkhalidwe weniweni wa kuyika ndi kutseka kwazinthu zomalizidwa zimathanso kudulidwa ndikusindikizidwa malinga ndi zosowa za makasitomala.Mapaketi osalowerera ndale amapezekanso.

Kachitidwe

| Yesani | Njira Yoyesera | Chofunikira |

| Kutentha kwa ntchito | Mtengo wa UL224 | -50 mpaka +125 ℃ |

| Kulimba kwamakokedwe | Chithunzi cha ASTM D2671 | ≥14 MPA |

| Elongation panthawi yopuma | Chithunzi cha ASTM D2671 | >400% |

| Elongation pa nthawi yopuma pambuyo kutentha ukalamba | ASTM D 2671 158℃/168hrs | ≥300% |

| Kutalika kwa nthawi yayitali | Mtengo wa UL224 | 0±5% |

| Kuchuluka kwa khoma | Chithunzi cha ASTM D2671 | <30% |

| Kuchedwa kwamoto | VW-1 | Pitani |

| Kuchuluka kwa resistivity | Chithunzi cha IEC93 | >1014Ω.m |

| Kukhazikika kwa mkuwa | UL224 | Pitani |

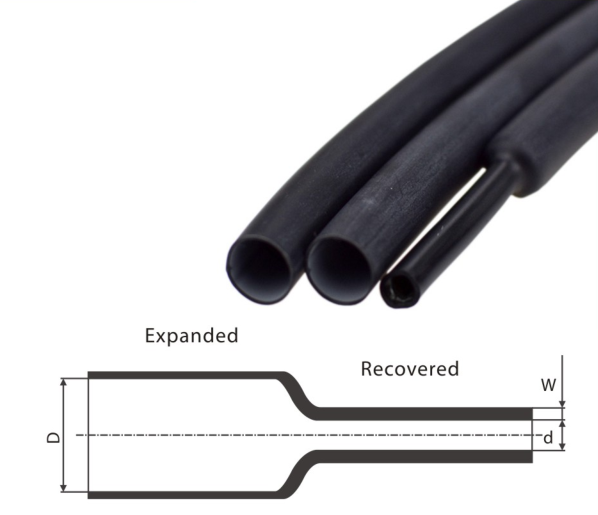

| Mtundu | Mulingo wa Diameter wa Ntchito(mm) | Kukulitsidwa(mm) | Kuchira(mm) | |

| D (mphindi) | d (zochuluka) | W (mphindi) | ||

| RSG-15/5 | 4.5-8 | 15 | 5 | 1.5 |

| RSG-20/8 | 6.5-14 | 20 | 8 | 1.8 |

| RSG-28/10 | 12-18 | 28 | 10 | 1.8 |

| RSG-35/14 | 17-27 | 35 | 14 | 2 |

| WRSG10-28/10 | 6.5-14 | 28 | 10 | 2.2 |

| WRSG10-34/14 | 17-27 | 34 | 14 | 2.3 |

| WRSG10-40/18 | 17-30 | 40 | 18 | 2.5 |

| WRSG10-50/20 | 17-35 | 50 | 20 | 2.5 |

| WRSG35-50/20 | 17-35 | 50 | 20 | 3 |

| WRSG35-60/22 | 21-45 | 60 | 22 | 3 |

| WRSG35-70/25 | 24-52 | 70 | 25 | 3 |