Kodi Socket Clevis ndi chiyani?

Socket clevis imadziwikanso kuti socket tongue ndi gawo lofunikira kwambiri paukadaulo wa pole line.

Amagwiritsidwa ntchito kwambiri pamizere yapamwamba, mizere yotumizira, ndi zingwe zamagetsi.

Ndi gawo lalikulu mu ma pole line hardware omwe nthawi zambiri amalumikiza socket mtundu wa insulator ndi chotchinga champhamvu.

Yang'anani izi:

Kulumikizana kwa socket clevis kumasiyanasiyana m'maiko osiyanasiyana kutengera malamulo omwe amalamulira ukadaulo wa pole line.

Choncho, ndikofunika kudziwa kugwirizana m'dziko lanu musanasankhe kuyitanitsa hardware.

Mwachitsanzo, ku Africa mtundu wa socket clevis womwe umagwiritsidwa ntchito umaphatikizapo:

Lilime la Socket limagwiritsidwa ntchito moyenera pa "Aluminium Conductor Steel Reinforced (ACSR)".

Kunja kwake kumakhala pakati pa 7 mm ndi 18.2mm (25 square millimeters ndi 150 square millimeters).

Amagwiritsidwanso ntchito pa "standard disc insulators a mpira ndi socket mtundu" wokhala ndi pini ya mpira wa 16 mm.

Chifukwa Chiyani Mukufunikira Socket Clevis?

Monga gawo lofunikira pazida zam'mbali, socket clevis imagwiritsidwa ntchito pazinthu zina.

- Imalumikiza insulator yamtundu wa socket ndi cholumikizira cholumikizira kapena chothandizira.

- Amagwiritsidwa ntchito ngati oyenera kujowina ma insulators a chingwe chimodzi.Zitsanzo ndi monga "mpira ndi socket, clevis ndi malirime kulumikizana, mbale za goli za insulators ya zingwe zambiri."

- Itha kugwiritsidwanso ntchito pamizere yamagetsi ngati ulalo wamagetsi.

- M'mizere yapamwamba, imagwiritsidwa ntchito ngati gawo lofunikira popereka mphamvu zamagetsi ku masitima apamtunda, mabasi a trolley, ndi tram.

- M'mizere yotumizira, ndi gawo la dongosolo lomwe limapangidwa kuti lithandizire kuyendetsa mafunde amtundu wina pamawayilesi.

Zigawo Zazikulu za Socket Clevis

Socket clevis ndi gulu la magawo ndi zigawo zosiyanasiyana.

Ngakhale kuti amasiyana m’mapangidwe ndi kaonekedwe, apa pali mbali zina zofala kwambiri.

1. Nangula maunyolo

Ndichidutswa chachitsulo chomwe nthawi zambiri chimakhala chopangidwa ndi U komanso chotetezedwa ndi pini ya clevis ndi bawuti.

Komanso, imatha kutetezedwa pogwiritsa ntchito chipika chachitsulo chokhala ndi hinged chomwe chimakhala ndi makina otsekera mwachangu.

Imakhala ngati ulalo waukulu pamakina osiyanasiyana olumikizirana pomwe amapereka maulumikizidwe ofulumira ndi kutulutsa.

2. Clevis pini

Ndi gawo lofunikira la cholumikizira cha clevis chomwe chili ndi zigawo zitatu zazikulu kuphatikiza clevis pin, clevis, ndi tang.

Mapiniwo ali amitundu iwiri kuphatikiza osawerengeka ndi ulusi.

Zikhomo zosawerengeka zili ndi mutu wooneka ngati dome kumapeto kwina ndipo mbali inayo, pali dzenje lopingasa.

Kuti pini ya clevis ikhale pamalo ake, pini yogawanika kapena pini ya cotter imagwiritsidwa ntchito.

Pini ya ulusi kumbali ina yapanga mitu mbali imodzi pamene mbali inayo imangokhala ya ulusi.

Mtedza umakhala wothandiza pamene pini iyenera kuikidwa.

3. Bawuti ya Clevis

Itha kugwiritsidwa ntchito m'malo mwa pini ya clevis ngakhale sichitengera kupsinjika komwe kumayendetsedwa ndi pini ya clevis.

Amapangidwa kuti atenge ndikusunga zolemetsa.

4. Pini ya cotter

Imadziwikanso ngati pini yogawanika kutengera dziko lomwe ikugwiritsidwa ntchito.

Kumbukirani, ichi ndi chitsulo chomwe chimakhala ngati chomangira chokhala ndi malekezero omwe amapindika pakuyika.

Amagwiritsidwa ntchito pomangirira zidutswa ziwiri zachitsulo pamodzi.

5. Bawuti

Ndi mtundu wa chomangira chomwe chimakhala ndi ulusi wachimuna wakunja womwe umagwiritsidwa ntchito ndipo uli ndi zofanana ndi wononga.

Nthawi zambiri amagwiritsidwa ntchito limodzi ndi mtedza.

Kumapeto kumodzi pali mutu wa bawuti ndipo mbali inayo ndi ulusi wamphongo wakunja.

6. Mtedza

Uwu ndi mtundu wa zomangira zomwe zimakhala ndi bowo la ulusi.

Amagwiritsidwa ntchito pamodzi ndi bawuti kuti amange kapena kulumikiza mbali zosiyanasiyana pamodzi.

Mgwirizanowu umayikidwa pamodzi ndi kuphatikiza kwa ulusi kupyolera mu kukangana.

Kupatula apo, zimatengera kutambasula ndi kupanikizana kwa zigawo zomwe zimagwirizanitsidwa pamodzi.

Mafotokozedwe aukadaulo a Socket Clevis

Musanagule socket clevis, ndikofunikira kulabadira izi zofunikira zaukadaulo:

1. Mtundu Wazinthu

Mitundu yazinthu zomwe zimagwiritsidwa ntchito popanga socket clevises ndi chitsulo ndi chitsulo.

Zidazi zimakondedwa chifukwa ndi zamphamvu zokwanira ndipo zimatha kupirira kulemera ndi kupsinjika.

2. Chithandizo cha Pamwamba

Ma socket clevise amadutsa munjira ya dip galvanization yotentha kuti asachite dzimbiri.

Kutentha kwa dip galvanization kumaphatikizapo kuviika chitsulo kapena chitsulo mu zinki kuti mbande ndikuchikhudza komaliza.

Chitsulo ndi chitsulo zimasambitsidwa mu zinki wosungunuka pa kutentha kwa madigiri 449 Celsius.

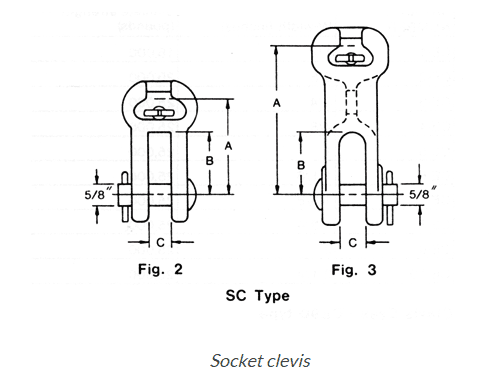

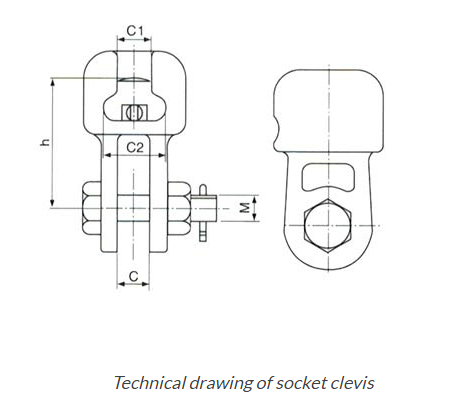

3. Makulidwe

Miyeso ya socket clevis imasiyana malinga ndi kukula kwa chipangizocho.

Komanso, kukula kwa socket clevis kumapangitsanso kukula kwake.

M'lifupi ndi kutalika kwake zimayesedwa mu millimeters pamene kulemera kumatsimikiziridwa mu kilogalamu.

4. Kupanga

Mapangidwe a socket clevis amadalira kampani yomwe imapanga.

Nthawi zambiri, wogula amakhala ndi chonena pamtundu wa mapangidwe omwe angafune komanso pa ntchitoyo, yomwe ingagwire.

Mapangidwe a socket clevis ayenera kugwirizana ndi ntchito yomwe amayenera kuchita.

5. Adavoteledwa Katundu

Katundu wovoteledwa pa socket clevis zimatengera kuchuluka kwa mphamvu yomwe idzagwire.

Wogula akuyenera kufotokoza ntchito yomwe clevis adzachita asanagule clevis.

Wopangayo amalangiza za socket clevis yoyenera kwambiri yokhudzana ndi katundu wovoteledwa.

6. Kulemera

Kulemera kwa socket clevis kumadalira kukula kwa chipangizocho, zomwe zimagwiritsidwa ntchito popanga chipangizocho.

Zida zina ndizolemera kuposa zina zomwe zimapangitsa kusiyana kwakukulu kwa kulemera kwake.

Miyeso monga m'lifupi, kutalika kwake kumasiyana komanso kulemera kwake kumasiyana.

Socket Clevis Manufacturing Process

Njira yopangira imayamba ndi kutentha, kuumba, kusungunula kenaka kutenthetsa dip galvanization.

Njira zomwe tazitchula pamwambapa ndi zowopsa ndipo nthawi zambiri zimasiyidwa kuti mafakitale azigwira ntchito.

Zipangizo: Chofunikira chachikulu ndi chitsulo ndi nkhungu ya socket clevis.

Makina ena amafunikira kuti achite izi omwe ndi okwera mtengo kwambiri.

Ichi ndichifukwa chake zasiyidwa kuti mafakitale akuluakulu monga Jingyoung apange.

Chenjezo: Njira yopangira clevis imaphatikizapo kugwira chitsulo pa kutentha kwambiri.

Ndi njira yowopsa ndipo muyenera kusamala mukamagwira chitsulo chosungunuka.

Muyeneranso kuvala zovala zodzitetezera ndi nsapato kuti zikutetezeni ku ngozi iliyonse yomwe ingachitike.

Miyeso: Iyi ndi njira yopezera kukula koyenera kwa zinthu zomwe zingagwiritsidwe ntchito popanga.

Zimapangidwa molingana ndi zomwe kasitomala amafunikira ngati pali ma socket clevises opangidwa mwachizolowezi.

Zinthuzo zimadulidwa mu zidutswa zofunikira zisanayambe kuchitidwa ndi njira zina.

Njira Yowotchera: Chitsulo chachitsulo chimatenthedwa pakatentha kwambiri kuti chisungunuke.

Chitsulo chachitsulo ndi chinthu chomwe chimakondedwa kwambiri chifukwa chimasungunuka ndi kutentha kochepa poyerekeza ndi zina.

Amasinthidwa kuchoka ku cholimba kukhala chamadzimadzi.

Chitsulo chosungunula chimatentha kwambiri ndipo kusamala kwambiri kuyenera kutengedwa panthawiyi.

Kupatula kusungunuka kotsika, chitsulo chotayidwa chimakhala ndi madzi abwino, machinability abwino, kukana kuvala komanso kusinthika kosagwirizana.

Izi zimapangitsa kukhala chinthu chokondedwa kwambiri chomwe chimagwiritsidwa ntchito popanga socket clevis.

Kuumba: Chitsulo chosungunula amatsanuliridwa mu nkhungu ya socket clevis.

Chikombolecho chimapangidwa m’njira yoti chikhale ndi bowo lofanana ndi lilime la socket.

Chitsulo chamadzimadzi chimatenga mawonekedwe a nkhungu yomwe ndi mawonekedwe a socket clevis.

Annealing: Njira yachitatu ndi annealing yomwe ndi njira yochizira kutentha yomwe imasintha microstructure yachitsulo.

Ndi njira yomwe imapangitsa socket clevis kukwaniritsa mphamvu zake, kuuma kwake, komanso ductility.

Kuziziritsa: sitepe yachinayi ndi kusiya chitsulo chowumbidwa kuti chizizire.

Kuzizira kumachedwa kulola nkhungu kukhalabe bwino osati kusweka.

Hot dip galvanization ndi njira yomaliza yomwe chitsulo choziziritsa chimadutsamo.

Izi zimaphatikizapo kuvala socket clevis pogwiritsa ntchito Zinc kuti itetezeke ku dzimbiri.

Socket clevis imaviikidwa mu zinc yosungunuka pa kutentha kwa madigiri 449 Celsius.

Pakadali pano, socket clevis yakonzeka ndipo imawunikiridwa kuti iwonetsetse kuti ndi yabwino kugwiritsidwa ntchito.

Momwe Mungakhalire Socket Clevis?

Kuyika socket clevis ndi njira yomwe imafuna kuti mizati ikhalepo musanayese kuyika.

Onetsetsani kuti zida zonse zilinso m'malo ndipo makwerero alipo kuti akukwezeni pamalo ofunikira.

- Zingwe za insulator ziyenera kulumikizidwa pansi musanakwere pamtengo.Kusonkhanitsa zingwe pansi kumakhala kosavuta poyerekeza ndi kuchita pamwamba pa mtengo.

- Ma insulators ndi zoyikira zimayikidwanso pansi komanso pamalo okwera.

- Kuonjezera mphamvu ya kukhazikitsa, makamaka pamene mikhalidwe yomanga ikuchitika, msonkhano wapansi umakonda.

- Kusonkhana pamalo okwera kumachitidwa pamene kumangako kuli ndi zoletsa.

- Panthawi yoyika ma insulators ndi zopangira pamalo okwera, ogwira ntchito amanyamula zida, zingwe ndi matepi achitsulo pamwamba pa makwerero.

- Malo oyika mkono wa mtanda amalembedwa ndipo mothandizidwa ndi chingwe, amakoka.

- Nkhono yamtanda imayikidwa m'malo mwake ndiye zida zina monga insulator ndi zingwe zotsekera zimayikidwa.

Socket clevis ndi gawo lofunikira kwambiri pazida zam'mizere ndipo imayikidwa ndi akatswiri.

Mtundu wa ntchito yomwe ikuyembekezeka kuchita imafuna kuti anthu odziwa zambiri ayiyikire chifukwa zolakwa sizivomerezedwa.

Ndizowopsanso kuyesa kukhazikitsa popanda kuthandizidwa ndi anthu ena kutanthauza kuti sizingachitike payekha.

Nthawi yotumiza: Sep-17-2020